Obtención de pectina empleando tecnologías emergentes de extracción verde: Revisión sistemática

DOI:

https://doi.org/10.55996/dekamuagropec.v6i1.334Palabras clave:

Ácido galacturónico, ecológico, grado de esterificación, tecnologías verdes, polisacáridoResumen

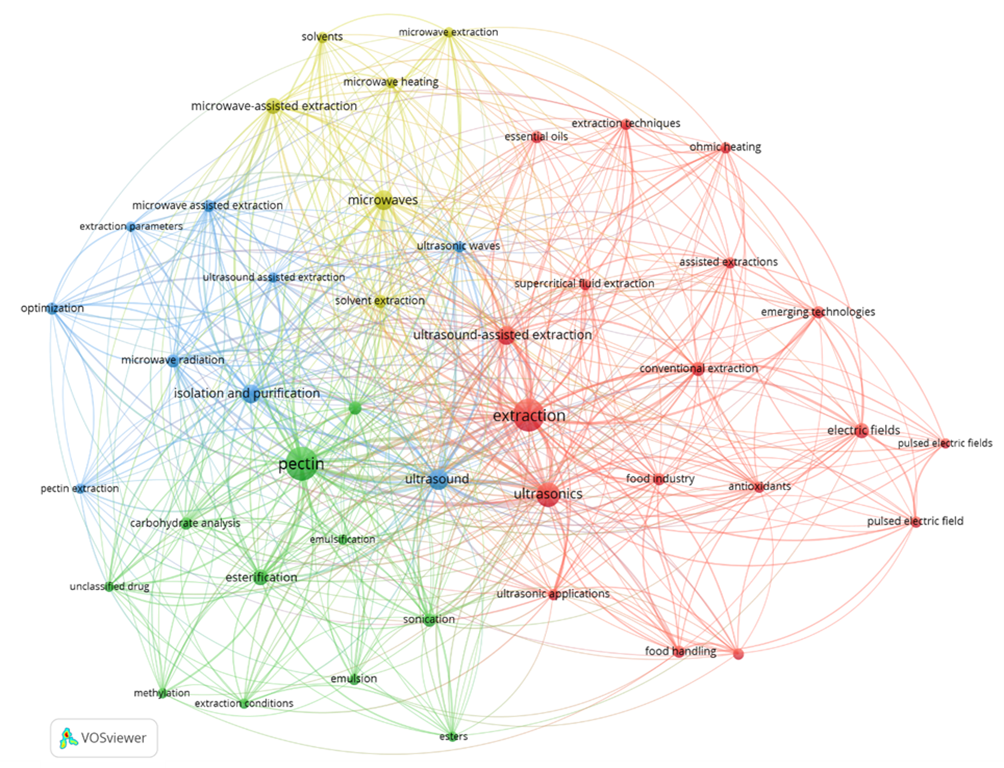

La pectina es un biopolímero versátil, que posee una propiedad dual de resistencia y flexibilidad, puede ser extraída de diversas fuentes orgánicas siguiendo metodologías ecológicas. El objetivo de la presente revisión fue identificar las tecnologías emergentes de extracción verde, empleadas para la obtención de pectina, así como analizar la tasa de rendimiento de extracción y los parámetros de operación adecuados para obtener pectinas con mejores características reológicas. Se empleó las bases de datos (Scopus, Scielo y Science Direct), siguiendo las directrices PRISMA y la estrategia PIO (Población, Intervención, Outputs), los cuales facilitaron formular las ecuaciones de búsqueda y a identificar los artículos más relevantes de los últimos 5 años. A través del análisis bibliométrico, se identificaron las tecnologías más prometedoras para la obtención de pectina como el ultrasonido; calentamiento óhmico; CO2 supercrítico; campo eléctrico pulsado; procesamiento de alta presión; radiofrecuencia; microondas y agua subcrítica, las cuales son tecnologías verdes que ofrecen pectinas con grados de esterificación superiores al 50%, clasificándolas como altas en metoxilo. En conclusión, las tecnologías innovadoras promueven una extracción más ecológica en comparación con los métodos tradicionales, ya que implican un menor consumo energético y reducen el uso de solventes tóxicos.

Descargas

Citas

Ajibade, B. O., & Ijabadeniyi, O. A. (2019). Effects of pectin and emulsifiers on the physical and nutritional qualities and consumer acceptability of wheat composite dough and bread. Journal of Food Science and Technology, 56(1), 83–92. https://doi.org/10.1007/s13197-018-3457-7

Al-Hilphy, A. R., Al-Musafer, A. M., & Gavahian, M. (2020). Pilot-scale ohmic heating-assisted extraction of wheat bran bioactive compounds: Effects of the extract on corn oil stability. Food Research International, 137, 109649. https://doi.org/10.1016/j.foodres.2020.109649

Aline de Moura, F., Macagnan, F. T., Lúcia de Oliveira Petkowicz, C., & Picolli da Silva, L. (2020). Partially hydrolyzed pectin extracted from passion fruit peel: Molar mass and physicochemical properties. Bioactive Carbohydrates and Dietary Fibre, 21, 100206. https://doi.org/10.1016/j.bcdf.2019.100206

Barbut, S., & Harper, A. (2020). Influence of relative humidity on dried Ca++-alginate films and composites made with soy and pectin. Italian Journal of Food Science, 32(1), 195–208. https://doi.org/10.14674/IJFS-1652

Caroço, R. F., Kim, B., Santacoloma, P. A., Abildskov, J., Lee, J. H., & Huusom, J. K. (2019). Analysis and model-based optimization of a pectin extraction process. Journal of Food Engineering, 244, 159–169. https://doi.org/10.1016/j.jfoodeng.2018.09.016

Chang, C.-K., Tsai, S.-Y., Gavahian, M., Cheng, K.-C., Hou, C.-Y., Yudhistira, B., Lin, S.-H., Santoso, S. P., & Hsieh, C.-W. (2023). Direct and alternating current electric fields affect pectin esterase and cellulase in tomato (Solanum lycopersicum L.) fruit during storage. Postharvest Biology and Technology, 205, 112495. https://doi.org/10.1016/j.postharvbio.2023.112495

Chen, S., Xiao, L., Li, S., Meng, T., Wang, L., & Zhang, W. (2022). The effect of sonication-synergistic natural deep eutectic solvents on extraction yield, structural and physicochemical properties of pectins extracted from mango peels. Ultrasonics Sonochemistry, 86, 106045. https://doi.org/10.1016/j.ultsonch.2022.106045

Cho, E.-H., Jung, H.-T., Lee, B.-H., Kim, H.-S., Rhee, J.-K., & Yoo, S.-H. (2019). Green process development for apple-peel pectin production by organic acid extraction. Carbohydrate Polymers, 204, 97–103. https://doi.org/10.1016/j.carbpol.2018.09.086

Ciriminna, R., Chavarría‐Hernández, N., Inés Rodríguez Hernández, A., & Pagliaro, M. (2015). Pectin: A new perspective from the biorefinery standpoint. Biofuels, Bioproducts and Biorefining, 9(4), 368–377. https://doi.org/10.1002/bbb.1551

Dranca, F., & Oroian, M. (2018). Extraction, purification and characterization of pectin from alternative sources with potential technological applications. Food Research International, 113, 327–350. https://doi.org/10.1016/j.foodres.2018.06.065

Duah, J., Agbenorhevi, J. K., Kpodo, F. M., & Saalia, F. K. (2025). Structural and functional properties of pectin extracted from African star apple. Food Chemistry Advances, 7, 101007. https://doi.org/10.1016/j.focha.2025.101007

Gerschenson, L. N., Fissore, E. N., Rojas, A. M., Idrovo Encalada, A. M., Zukowski, E. F., & Higuera Coelho, R. A. (2021). Pectins obtained by ultrasound from agroindustrial by-products. Food Hydrocolloids, 118, 106799. https://doi.org/10.1016/j.foodhyd.2021.106799

Gharibzahedi, S. M. T., Smith, B., & Guo, Y. (2019). Ultrasound-microwave assisted extraction of pectin from fig (Ficus carica L.) skin: Optimization, characterization and bioactivity. Carbohydrate Polymers, 222, 114992. https://doi.org/10.1016/j.carbpol.2019.114992

Gómez, B., Munekata, P. E. S., Gavahian, M., Barba, F. J., Martí-Quijal, F. J., Bolumar, T., Campagnol, P. C. B., Tomasevic, I., & Lorenzo, J. M. (2019). Application of pulsed electric fields in meat and fish processing industries: An overview. Food Research International, 123, 95–105. https://doi.org/10.1016/j.foodres.2019.04.047

Guandalini, B. B. V., Rodrigues, N. P., & Marczak, L. D. F. (2019). Sequential extraction of phenolics and pectin from mango peel assisted by ultrasound. Food Research International, 119, 455–461. https://doi.org/10.1016/j.foodres.2018.12.011

Hou, Z., Luan, L., Hu, X., Chen, S., & Ye, X. (2022). Beneficial effects of high pressure processing on the interaction between RG-I pectin and cyanidin-3-glucoside. Food Chemistry, 383, 132373. https://doi.org/10.1016/j.foodchem.2022.132373

Inayati, Puspita, R. I., & Fajrin, V. L. (2018). Extraction of pectin from passion fruit rind (Passiflora edulis var. flavicarpa Degener) for edible coating. 030002. https://doi.org/10.1063/1.5024061

Jiao, Y., Tang, J., Wang, Y., & Koral, T. L. (2018). Radio-Frequency Applications for Food Processing and Safety. Annual Review of Food Science and Technology, 9(1), 105–127. https://doi.org/10.1146/annurev-food-041715-033038

Kamal, M. M., Ali, M. R., Hossain, A., & Shishir, M. R. I. (2020). Optimization of microwave‐assisted extraction of pectin from Dillenia indica fruit and its preliminary characterization. Journal of Food Processing and Preservation, 44(6). https://doi.org/10.1111/jfpp.14466

Karbuz, P., & Tugrul, N. (2021). Microwave and ultrasound assisted extraction of pectin from various fruits peel. Journal of Food Science and Technology, 58(2), 641–650. https://doi.org/10.1007/s13197-020-04578-0

Karim, R., Nahar, K., Zohora, F. T., Islam, M. M., Bhuiyan, R. H., Jahan, M. S., & Shaikh, M. A. A. (2022). Pectin from lemon and mango peel: Extraction, characterisation and application in biodegradable film. Carbohydrate Polymer Technologies and Applications, 4, 100258. https://doi.org/10.1016/j.carpta.2022.100258

Klinchongkon, K., Khuwijitjaru, P., & Adachi, S. (2018). Properties of subcritical water-hydrolyzed passion fruit ( Passiflora edulis ) pectin. Food Hydrocolloids, 74, 72–77. https://doi.org/10.1016/j.foodhyd.2017.07.034

Kumar, K., Srivastav, S., & Sharanagat, V. S. (2021). Ultrasound assisted extraction (UAE) of bioactive compounds from fruit and vegetable processing by-products: A review. Ultrasonics Sonochemistry, 70, 105325. https://doi.org/10.1016/j.ultsonch.2020.105325

Kumar, M., Tomar, M., Saurabh, V., Mahajan, T., Punia, S., Contreras, M. del M., Rudra, S. G., Kaur, C., & Kennedy, J. F. (2020). Emerging trends in pectin extraction and its anti-microbial functionalization using natural bioactives for application in food packaging. Trends in Food Science & Technology, 105, 223–237. https://doi.org/10.1016/j.tifs.2020.09.009

Lal, A. M. N., Prince, M. V., Kothakota, A., Pandiselvam, R., Thirumdas, R., Mahanti, N. K., & Sreeja, R. (2021). Pulsed electric field combined with microwave-assisted extraction of pectin polysaccharide from jackfruit waste. Innovative Food Science & Emerging Technologies, 74, 102844. https://doi.org/10.1016/j.ifset.2021.102844

Liew, S. Q., Teoh, W. H., Tan, C. K., Yusoff, R., & Ngoh, G. C. (2018). Subcritical water extraction of low methoxyl pectin from pomelo (Citrus grandis (L.) Osbeck) peels. International Journal of Biological Macromolecules, 116, 128–135. https://doi.org/10.1016/j.ijbiomac.2018.05.013

Ma, J., Tong, P., Chen, Y., Wang, Y., Ren, H., Gao, Z., Yue, T., & Long, F. (2022). The inhibition of pectin oligosaccharides on degranulation of RBL-2H3 cells from apple pectin with high hydrostatic pressure assisted enzyme treatment. Food Chemistry, 371, 131097. https://doi.org/10.1016/j.foodchem.2021.131097

Marić, M., Grassino, A. N., Zhu, Z., Barba, F. J., Brnčić, M., & Rimac Brnčić, S. (2018). An overview of the traditional and innovative approaches for pectin extraction from plant food wastes and by-products: Ultrasound-, microwaves-, and enzyme-assisted extraction. Trends in Food Science & Technology, 76, 28–37. https://doi.org/10.1016/j.tifs.2018.03.022

Mekala, S., Silva, E. K., & Saldaña, M. D. A. (2022). Ultrasound-assisted production of emulsion-filled pectin hydrogels to encapsulate vitamin complex: Impact of the addition of xylooligosaccharides, ascorbic acid and supercritical CO2 drying. Innovative Food Science & Emerging Technologies, 76, 102907. https://doi.org/10.1016/j.ifset.2021.102907

Moens, L. G., De Laet, E., Van Wambeke, J., Van Loey, A. M., & Hendrickx, M. E. G. (2020). Pulsed electric field and mild thermal processing affect the cooking behaviour of carrot tissues (Daucus carota) and the degree of methylesterification of carrot pectin. Innovative Food Science & Emerging Technologies, 66, 102483. https://doi.org/10.1016/j.ifset.2020.102483

Mohamed, H. (2016). Extraction and Characterization of Pectin from Grapefruit Peels. MOJ Food Processing & Technology, 2(1). https://doi.org/10.15406/mojfpt.2016.02.00029

Muñoz-Almagro, N., Montilla, A., Moreno, F. J., & Villamiel, M. (2017). Modification of citrus and apple pectin by power ultrasound: Effects of acid and enzymatic treatment. Ultrasonics Sonochemistry, 38, 807–819. https://doi.org/10.1016/j.ultsonch.2016.11.039

Muñoz-Almagro, N., Valadez-Carmona, L., Mendiola, J. A., Ibáñez, E., & Villamiel, M. (2019). Structural characterisation of pectin obtained from cacao pod husk. Comparison of conventional and subcritical water extraction. Carbohydrate Polymers, 217, 69–78. https://doi.org/10.1016/j.carbpol.2019.04.040

Ndayishimiye, J., Lim, D. J., & Chun, B. S. (2018). Antioxidant and antimicrobial activity of oils obtained from a mixture of citrus by-products using a modified supercritical carbon dioxide. Journal of Industrial and Engineering Chemistry, 57, 339–348. https://doi.org/10.1016/j.jiec.2017.08.041

Ninčević Grassino, A., Ostojić, J., Miletić, V., Djaković, S., Bosiljkov, T., Zorić, Z., Ježek, D., Rimac Brnčić, S., & Brnčić, M. (2020). Application of high hydrostatic pressure and ultrasound-assisted extractions as a novel approach for pectin and polyphenols recovery from tomato peel waste. Innovative Food Science & Emerging Technologies, 64, 102424. https://doi.org/10.1016/j.ifset.2020.102424

Novickij, V., Stanevičienė, R., Staigvila, G., Gruškienė, R., Sereikaitė, J., Girkontaitė, I., Novickij, J., & Servienė, E. (2020). Effects of pulsed electric fields and mild thermal treatment on antimicrobial efficacy of nisin-loaded pectin nanoparticles for food preservation. LWT, 120, 108915. https://doi.org/10.1016/j.lwt.2019.108915

Pagano, I., Campone, L., Celano, R., Piccinelli, A. L., & Rastrelli, L. (2021). Green non-conventional techniques for the extraction of polyphenols from agricultural food by-products: A review. Journal of Chromatography A, 1651, 462295. https://doi.org/10.1016/j.chroma.2021.462295

Pangestu, R., Amanah, S., Juanssilfero, A. B., Yopi, & Perwitasari, U. (2020). Response surface methodology for microwave-assisted extraction of pectin from cocoa pod husk (Theobroma cacao) mediated by oxalic acid. Journal of Food Measurement and Characterization, 14(4), 2126–2133. https://doi.org/10.1007/s11694-020-00459-4

Picot-Allain, M. C. N., Ramasawmy, B., & Emmambux, M. N. (2022). Extraction, Characterisation, and Application of Pectin from Tropical and Sub-Tropical Fruits: A Review. Food Reviews International, 38(3), 282–312. https://doi.org/10.1080/87559129.2020.1733008

Polanco-Lugo, E., Martínez-Castillo, J. I., Cuevas-Bernardino, J. C., González-Flores, T., Valdez-Ojeda, R., Pacheco, N., & Ayora-Talavera, T. (2019). Citrus pectin obtained by ultrasound-assisted extraction: Physicochemical, structural, rheological and functional properties. CyTA - Journal of Food, 17(1), 463–471. https://doi.org/10.1080/19476337.2019.1600036

Ran, X., Zhang, M., Wang, Y., & Adhikari, B. (2019). Novel technologies applied for recovery and value addition of high value compounds from plant byproducts: A review. Critical Reviews in Food Science and Nutrition, 59(3), 450–461. https://doi.org/10.1080/10408398.2017.1377149

Randriampenohaja, A. R. J., Rasolohery, C. A., Rakotovao, M., & Rasoarahona, J. R. E. (2021). Influences of the pH, the liquid/solid ratio, and the mixing of the wastes of mango, passion fruit and Bambara groundnut on the extraction yield of pectin. International Journal of Scientific and Research Publications (IJSRP), 11(7), 226–235. https://doi.org/10.29322/IJSRP.11.07.2021.p11529

Rivadeneira, J. P., Wu, T., Ybanez, Q., Dorado, A. A., Migo, V. P., Nayve, F. R. P., & Castillo-Israel, K. A. T. (2020). Microwave-Assisted Extraction of Pectin from “Saba” Banana Peel Waste: Optimization, Characterization, and Rheology Study. International Journal of Food Science, 2020, 1–9. https://doi.org/10.1155/2020/8879425

Rivas, M. Á., Casquete, R., de Guía Córdoba, M., Benito, M. J., Hernández, A., Ruiz-Moyano, S., & Martín, A. (2021). Functional properties of extracts and residual dietary fibre from pomegranate (Punica granatum L.) peel obtained with different supercritical fluid conditions. LWT, 145, 111305. https://doi.org/10.1016/j.lwt.2021.111305

Rubio-Senent, F., Rodríguez-Gutiérrez, G., Lama-Muñoz, A., & Fernández-Bolaños, J. (2015). Pectin extracted from thermally treated olive oil by-products: Characterization, physico-chemical properties, in vitro bile acid and glucose binding. Food Hydrocolloids, 43, 311–321. https://doi.org/10.1016/j.foodhyd.2014.06.001

Sabater, C., Sabater, V., Olano, A., Montilla, A., & Corzo, N. (2020). Ultrasound-assisted extraction of pectin from artichoke by-products. An artificial neural network approach to pectin characterisation. Food Hydrocolloids, 98, 105238. https://doi.org/10.1016/j.foodhyd.2019.105238

Saberian, H., Hamidi‐Esfahani, Z., Ahmadi Gavlighi, H., Banakar, A., & Barzegar, M. (2018). The potential of ohmic heating for pectin extraction from orange waste. Journal of Food Processing and Preservation, 42(2), e13458. https://doi.org/10.1111/jfpp.13458

Santo Domingo, C., Otálora González, C., Navarro, D., Stortz, C., Rojas, A. M., Gerschenson, L. N., & Fissore, E. N. (2021). Enzyme assisted extraction of pectin and inulin enriched fractions isolated from microwave treated Cynara cardunculus tissues. International Journal of Food Science & Technology, 56(1), 242–249. https://doi.org/10.1111/ijfs.14625

Sayah, M. Y., Chabir, R., Benyahia, H., Rodi Kandri, Y., Ouazzani Chahdi, F., Touzani, H., & Errachidi, F. (2016). Yield, Esterification Degree and Molecular Weight Evaluation of Pectins Isolated from Orange and Grapefruit Peels under Different Conditions. PLOS ONE, 11(9), e0161751. https://doi.org/10.1371/journal.pone.0161751

Sengar, A. S., Rawson, A., Muthiah, M., & Kalakandan, S. K. (2020). Comparison of different ultrasound assisted extraction techniques for pectin from tomato processing waste. Ultrasonics Sonochemistry, 61, 104812. https://doi.org/10.1016/j.ultsonch.2019.104812

Shao, L., Zhao, Y., Zou, B., Li, X., & Dai, R. (2021). Ohmic heating in fruit and vegetable processing: Quality characteristics, enzyme inactivation, challenges and prospective. Trends in Food Science & Technology, 118, 601–616. https://doi.org/10.1016/j.tifs.2021.10.009

Sharifi, A., Hamidi-Esfahani, Z., Ahmadi Gavlighi, H., & Saberian, H. (2022). Assisted ohmic heating extraction of pectin from pomegranate peel. Chemical Engineering and Processing - Process Intensification, 172, 108760. https://doi.org/10.1016/j.cep.2021.108760

Shivamathi, C. S., Moorthy, I. G., Kumar, R. V., Soosai, M. R., Maran, J. P., Kumar, R. S., & Varalakshmi, P. (2019). Optimization of ultrasound assisted extraction of pectin from custard apple peel: Potential and new source. Carbohydrate Polymers, 225, 115240. https://doi.org/10.1016/j.carbpol.2019.115240

Sucheta, Misra, N. N., & Yadav, S. K. (2020). Extraction of pectin from black carrot pomace using intermittent microwave, ultrasound and conventional heating: Kinetics, characterization and process economics. Food Hydrocolloids, 102, 105592. https://doi.org/10.1016/j.foodhyd.2019.105592

Sutapa, B. M., Dhruti, Avlani, P. G., & Gopa, R. B. (2018). Therapeutic and pharmaceutical benefits of native and modified plant pectin. Journal of Medicinal Plants Research, 12(1), 1–6. https://doi.org/10.5897/JMPR2017.6542

Tan, C., Kong, Y., Tong, Y., Deng, H., Wang, M., Zhao, Y., Wan, M., Lin, S., Liu, X., Meng, X., & Ma, Y. (2021). Anti-apoptotic effects of high hydrostatic pressure treated cyanidin-3-glucoside and blueberry pectin complexes on lipopolysaccharide-induced inflammation in Caco-2 cells. Journal of Functional Foods, 86, 104709. https://doi.org/10.1016/j.jff.2021.104709

Tan, C., Li, D., Wang, H., Tong, Y., Zhao, Y., Deng, H., Kong, Y., Shu, C., Yan, T., & Meng, X. (2021). Effects of high hydrostatic pressure on the binding capacity, interaction, and antioxidant activity of the binding products of cyanidin-3-glucoside and blueberry pectin. Food Chemistry, 344, 128731. https://doi.org/10.1016/j.foodchem.2020.128731

Tsuru, C., Umada, A., Noma, S., Demura, M., & Hayashi, N. (2021). Extraction of Pectin from Satsuma Mandarin Orange Peels by Combining Pressurized Carbon Dioxide and Deionized Water: a Green Chemistry Method. Food and Bioprocess Technology, 14(7), 1341–1348. https://doi.org/10.1007/s11947-021-02644-9

Tunç, M. T., & Odabaş, H. İ. (2021). Single-step recovery of pectin and essential oil from lemon waste by ohmic heating assisted extraction/hydrodistillation: A multi-response optimization study. Innovative Food Science & Emerging Technologies, 74, 102850. https://doi.org/10.1016/j.ifset.2021.102850

Urrútia, G., & Bonfill, X. (2010). Declaración PRISMA: una propuesta para mejorar la publicación de revisiones sistemáticas y metaanálisis. Medicina Clínica, 135(11), 507–511. https://doi.org/10.1016/j.medcli.2010.01.015

Wan, L., Chen, Q., Huang, M., Liu, F., & Pan, S. (2019). Physiochemical, rheological and emulsifying properties of low methoxyl pectin prepared by high hydrostatic pressure-assisted enzymatic, conventional enzymatic, and alkaline de-esterification: A comparison study. Food Hydrocolloids, 93, 146–155. https://doi.org/10.1016/j.foodhyd.2019.02.022

Wellala, C. K. D., Bi, J., Liu, X., Wu, X., Lyu, J., Liu, J., Liu, D., & Guo, C. (2022). Effect of high pressure homogenization on water-soluble pectin characteristics and bioaccessibility of carotenoids in mixed juice. Food Chemistry, 371, 131073. https://doi.org/10.1016/j.foodchem.2021.131073

Xie, F., Zhang, W., Lan, X., Gong, S., Wu, J., & Wang, Z. (2018). Effects of high hydrostatic pressure and high pressure homogenization processing on characteristics of potato peel waste pectin. Carbohydrate Polymers, 196, 474–482. https://doi.org/10.1016/j.carbpol.2018.05.061

Xu, S.-Y., Liu, J.-P., Huang, X., Du, L.-P., Shi, F.-L., Dong, R., Huang, X.-T., Zheng, K., Liu, Y., & Cheong, K.-L. (2018). Ultrasonic-microwave assisted extraction, characterization and biological activity of pectin from jackfruit peel. LWT, 90, 577–582. https://doi.org/10.1016/j.lwt.2018.01.007

Yang, X., Nisar, T., Liang, D., Hou, Y., Sun, L., & Guo, Y. (2018). Low methoxyl pectin gelation under alkaline conditions and its rheological properties: Using NaOH as a pH regulator. Food Hydrocolloids, 79, 560–571. https://doi.org/10.1016/j.foodhyd.2017.12.006

Yang, Y., Wang, Z., Hu, D., Xiao, K., & Wu, J.-Y. (2018). Efficient extraction of pectin from sisal waste by combined enzymatic and ultrasonic process. Food Hydrocolloids, 79, 189–196. https://doi.org/10.1016/j.foodhyd.2017.11.051

Yao, Y., Sun, Y., Cui, B., Fu, H., Chen, X., & Wang, Y. (2021). Radio frequency energy inactivates peroxidase in stem lettuce at different heating rates and associate changes in physiochemical properties and cell morphology. Food Chemistry, 342, 128360. https://doi.org/10.1016/j.foodchem.2020.128360

Zaid, R. M., Mishra, P., Siti Noredyani, A. R., Tabassum, S., Ab Wahid, Z., & Mimi Sakinah, A. M. (2020). Proximate characteristics and statistical optimization of ultrasound-assisted extraction of high-methoxyl-pectin from Hylocereus polyrhizus peels. Food and Bioproducts Processing, 123, 134–149. https://doi.org/10.1016/j.fbp.2020.06.011

Zaid, R. M., Mishra, P., Tabassum, S., Wahid, Z. A., & Sakinah, A. M. M. (2019). High methoxyl pectin extracts from Hylocereus polyrhizus’s peels: Extraction kinetics and thermodynamic studies. International Journal of Biological Macromolecules, 141, 1147–1157. https://doi.org/10.1016/j.ijbiomac.2019.09.017

Zdunek, A., Pieczywek, P. M., & Cybulska, J. (2021). The primary, secondary, and structures of higher levels of pectin polysaccharides. Comprehensive Reviews in Food Science and Food Safety, 20(1), 1101–1117. https://doi.org/10.1111/1541-4337.12689

Zhang, F., Zhang, L., Chen, J., Du, X., Lu, Z., Wang, X., Yi, Y., Shan, Y., Liu, B., Zhou, Y., Wang, X., & Lü, X. (2022). Systematic evaluation of a series of pectic polysaccharides extracted from apple pomace by regulation of subcritical water conditions. Food Chemistry, 368, 130833. https://doi.org/10.1016/j.foodchem.2021.130833

Zhang, S., Wu, J., Zheng, J., Peng, Y., Zhao, J., Pan, X., & Lao, F. (2025). Deep eutectic solvents/water systems in different pH for extracting pectin from mango peel: Analysis of physicochemical and structural properties. Food Hydrocolloids, 168, 111578. https://doi.org/10.1016/j.foodhyd.2025.111578

Zheng, J., Li, H., Wang, D., Li, R., Wang, S., & Ling, B. (2021). Radio frequency assisted extraction of pectin from apple pomace: Process optimization and comparison with microwave and conventional methods. Food Hydrocolloids, 121, 107031. https://doi.org/10.1016/j.foodhyd.2021.107031

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2025 Joselin Paucarchuco Soto, Brenda Rocío Montes Minaya, Jherry Lobaton Phocco Minaya, Javier Ruben Romero Cahuana, Yesenia Milagros Turpo Mamani

Esta obra está bajo una licencia internacional Creative Commons Atribución 4.0.

Los autores que publican en esta revista aceptan los siguientes términos:

- Los autores conservan los derechos de autor y conceden a la revista el derecho publicación con la obra, simultáneamente licenciada bajo una licencia de Creative Commons CC By que permite a otros compartir el trabajo, pero citando la publicación inicial en esta revista.

- Los autores pueden celebrar acuerdos contractuales adicionales separados para la distribución no exclusiva de la versión publicada de la obra de la revista (por ejemplo, publicarla en un repositorio institucional o publicarla en un libro), pero citando la publicación inicial en esta revista.

- Se permite y anima a los autores a publicar su trabajo en línea (por ejemplo, en repositorios institucionales o en su sitio web) antes y durante el proceso de presentación, ya que puede conducir a intercambios productivos, así como una mayor citación del trabajo publicado (https://web-archive.southampton.ac.uk/opcit.eprints.org/oacitation-biblio.html)